Product Description

Product Description

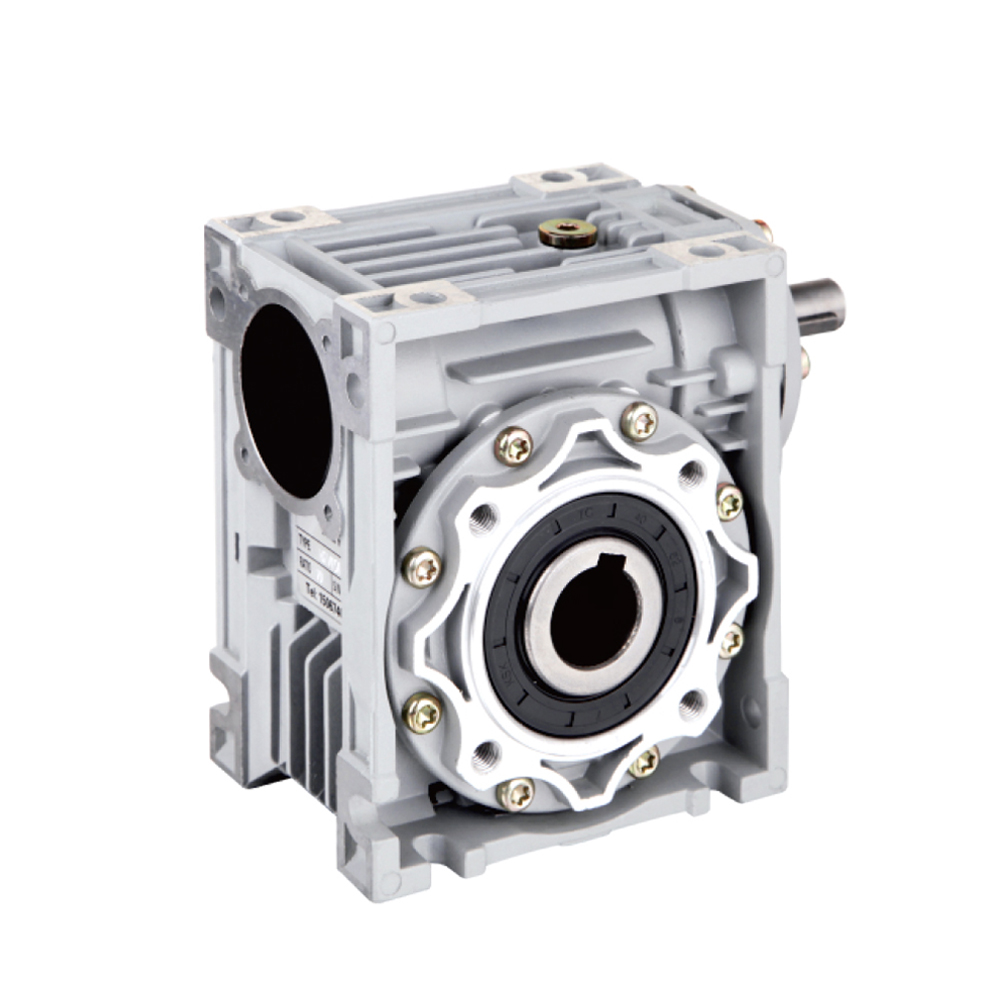

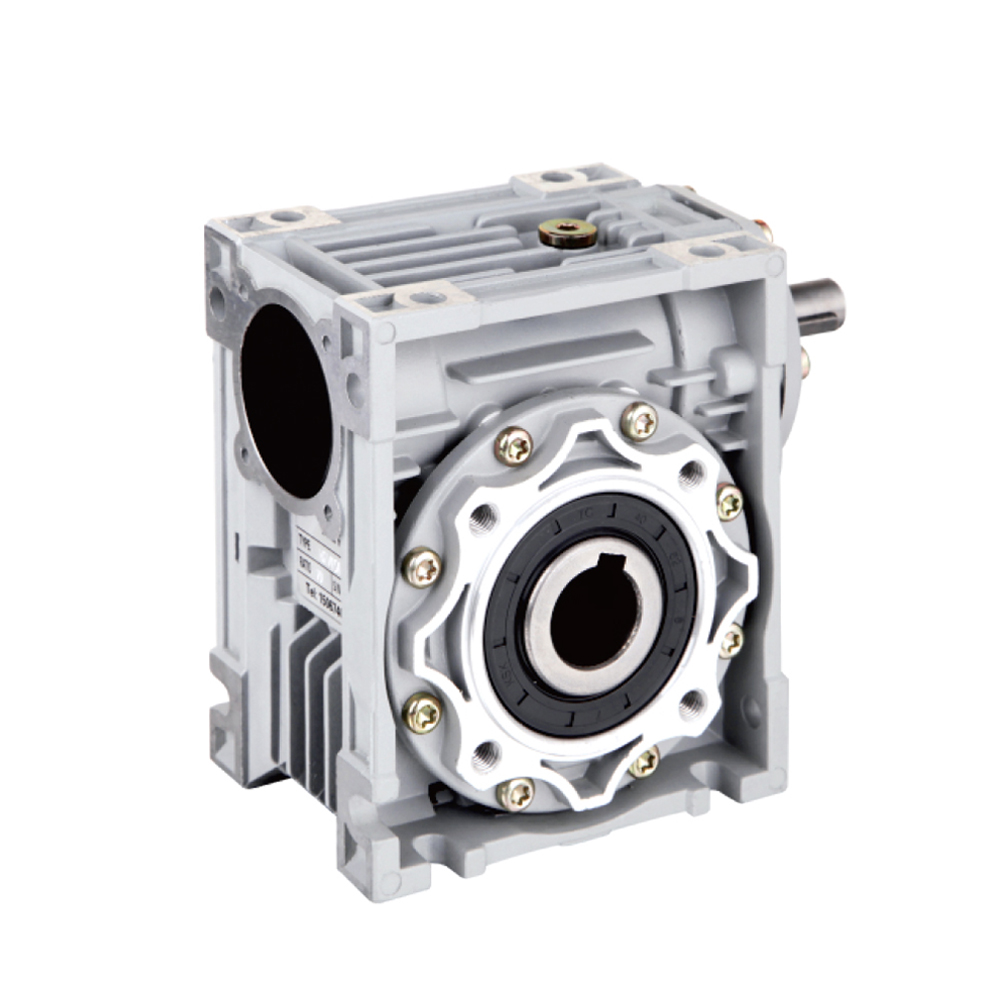

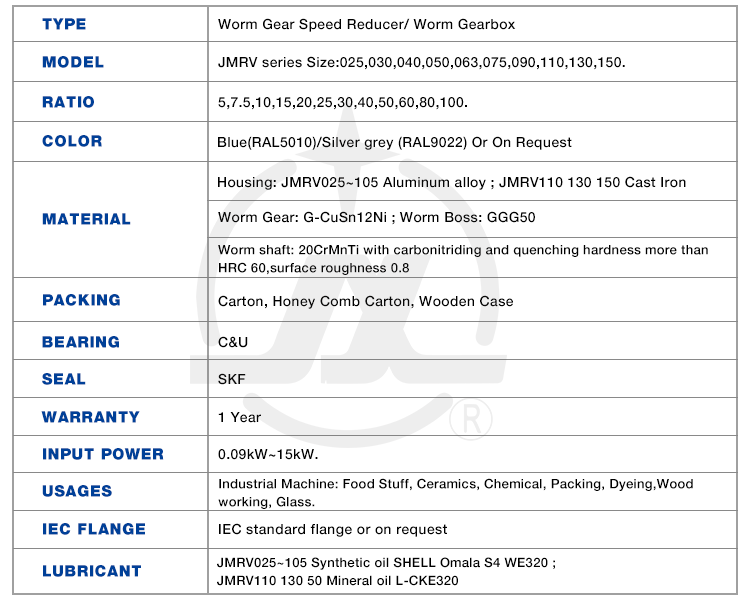

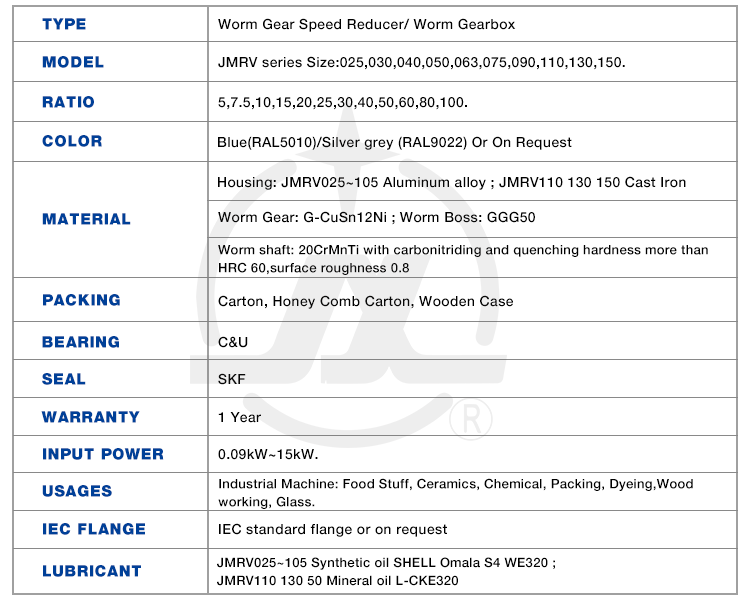

| product name | gearbox drive shaft |

| Product number | 2201-0571 |

| Specification | standard |

| Material | Metal |

| performance | hight |

| Application classification | drive shaft |

| Applicable models | Yutong/zhongtong/haige bus |

| Origin | China |

| Package | Carton |

| Transportation method | According to customer requirements |

Detailed Photos

Product material number

Our company operates a full range of accessories for buses and trucks of multiple brands. If the product you need is not on my list, please send me an email and I will send you the exact information and price based on your description or item number.

| 2201-05711 | 2201-01587 | 2201-0571 | 2201-01405 | 2201-00948 | 2201-5713 |

| 2201-01818 | 2201-0 0571 | 2201-57169 | 2201-02620 | 2201-00145 | 2201-03263 |

| 2201-5713 | 2201-00495 | 2201-00179 | 2201-57198 | 2201-01391 | 2201-00696 |

| 2201-00687 | 2201-01863 | 2201-05710 | 2201-00696 | 2201-01707 | 2201-01700 |

| 2201-0571 | 2201-00012 | 2201-00038 | 2201-00082 | 2201-00082A | 2201-00087 |

| 2201-00089A | 2201-00099 | 2201-5711 | 2201-5718 | 2201-5719 | 2201-00127 |

| 2201-00129 | 2201-00166A | 2201-00171 | 2201-00175 | 2201-00181 | 2201-5713 |

| 2201-05712 | 2201-05711 | 2201-05711A | 2201-05712 | 2201-05710 | 2201-05711 |

| 2201-5716 | 2201-5712 | 2201-5718 | 2201-0571 | 2201-0571 | 2201-0571 |

| 2201-0 0571 | 2201-00388 | 2201-00390 | 2201-00390A | 2201-00406 | 2201-0571 |

| 2201-00428 | 2201-00441 | 2201-00447 | 2201-00495 | 2201-0571 | 2201-0571 |

| 2201-00544 | 2201-0 0571 | 2201-00581 | 2201-00587 | 2201-00588 | 2201-00589 |

| 2201-00590 | 2201-00602 | 2201-0 0571 | 2201-00652 | 2201-00654 | 2201-00655 |

| 2201-00658 | 2201-00664 | 2201-00667 | 2201-00686 | 2201-00687 | 2201-00696 |

| 2201-00729 | 2201-0571 | 2201-0 0571 | 2201-0571 | 2201-571 | 2201-00801 |

| 2201-00808 | 2201-0571 | 2201-0 0571 | 2201-0 0571 | 2201-0 0571 | 2201-00881 |

| 2201-00948 | 2201-571 | 2201-0 0571 | 2201-57126 | 2201-57138 | 2201-57143 |

| 2201-57152 | 2201-57178 | 2201-57184 | 2201-57187 | 2201-01128 | 2201-01215 |

| 2201-01284 | 2201-01297 | 2201-01328 | 2201-01341 | 2201-01342 | 2201-01345 |

| 2201-01402 | 2201-01404 | 2201-01405 | 2201-01455 | 2201-01459 | 2201-01460 |

| 2201-01462 | 2201-01545 | 2201-01555 | 2201-01557 | 2201-01586 | 2201-01587 |

| 2201-01588 | 2201-01589 | 2201-01593 | 2201-01620 | 2201-01623 | 2201-01624 |

| 2201-01633 | 2201-01634 | 2201-01642 | 2201-01693 | 2201-01702 | 2201-01709 |

| 2201-01720 | 2201-01726 | 2201-01755 | 2201-01759 | 2201-01762 | 2201-01818 |

| 2201-01827 | 2201-01844 | 2201-01847 | 2201-01849 | 2201-01857 | 2201-01860 |

| 2201-01863 | 2201-01864 | 2201-01981 | 2201-01991 | 2201-57177 | 2201-57178 |

| 2201-57120 | 2201-57155 | 2201-57133 | 2201-57140 | 2201-57154 | 2201-57159 |

| 2201-57161 | 2201-57173 | 2201-57108 | 2201-02605 | 2201-02615 | 2201-02620 |

| 2201-02621 | 2201-02634 | 2201-57155 | 2201-57156 | 2201-57122 | 2201-57125 |

| 2201-57130 | 2201-57169 | 2201- 0571 1 | 2201-5718 | 2201-5713 | 2201-03394 |

| 2201-03453 | 5904- 0571 8 | 5904- 0571 9 | 5904-05017 | 5904-05018 | 5904-05019 |

| 5904-05062 | 5904-05063 | 5904-05064 | 5904- 0571 3 | 5904- 0571 4 | 5904- 0571 5 |

| 5912-05265 | 5912-05266 | 5913-5719 | 5913-5710 | 5913-5711 | 5913-05204 |

| 5913-05205 | 5914-57188 | 5914-57189 |

Shipping scenario

Our Advantages

FAQ

Q1. How do you correctly identify the products you need?

A:Supply part number,we can check directly.

Engine and gearbox parts;if you don’t know part code,try to found engine or gear model and number.

Q2. What are your packaging conditions?

A: Generally, the goods are packed in neutral white boxes or brown cartons.

If you have a legally registered patent, the goods can be packed in your branded boxes after obtaining your authorization letter.

Q3. What are your payment terms?

A: T/T 30% as deposit, 70% before delivery. Photos of the product and packaging will be shown to you before the balance is paid.

Q4 How is your delivery time?

A: Generally, it takes 30 days after receiving the advance payment.

The specific delivery time depends on the items and quantity of the order.

Q5. Can you produce according to samples?

A: Yes, it can be developed according to your samples or technical drawings.

Q6. Do you test all goods before delivery?

A: Yes, 100% tested before delivery.

Q7: How do you make our business long-term and good relationship?

A: 1. Good quality and competitive prices ensure our customers benefit;

2.We respect every customer as our friend, we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Standard After-Sales |

|---|---|

| Condition: | New |

| Color: | Black |

| Certification: | CE, DIN, ISO |

| Type: | C.V. Joint |

| Application Brand: | Yutong |

| Samples: |

US$ 120/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do drivelines handle variations in load and torque during operation?

Drivelines are designed to handle variations in load and torque during operation by incorporating various components and mechanisms that optimize power transmission and mitigate the effects of these variations. Let’s delve into the ways drivelines handle load and torque variations:

1. Flexible Couplings:

Drivelines often utilize flexible couplings, such as universal joints or constant velocity (CV) joints, to accommodate misalignment and angular variations between connected components. These couplings allow for smooth power transmission even when there are slight misalignments or changes in angles. They can compensate for variations in load and torque by flexing and adjusting their angles, thereby reducing stress on the driveline components.

2. Torque Converters:

In some driveline systems, such as those found in automatic transmissions, torque converters are employed. Torque converters use hydraulic principles to transmit power between the engine and the drivetrain. They provide a degree of slip, which allows for torque multiplication and smooth power delivery, especially during low-speed and high-load conditions. Torque converters help manage variations in torque by absorbing and dampening sudden changes, ensuring smoother operation.

3. Clutches:

Clutches play a critical role in drivelines, particularly in manual transmissions or systems that require torque control. Clutches engage and disengage the power flow between the engine and the drivetrain. By engaging or disengaging the clutch, the driveline can handle variations in load and torque. For instance, when starting a vehicle from a standstill, the clutch gradually engages to transmit power smoothly and prevent abrupt torque surges.

4. Gearboxes and Transmission Systems:

Drivelines often incorporate gearboxes and transmissions that provide multiple gear ratios. These systems allow for varying torque and speed outputs, enabling the driveline to adapt to different load conditions. By changing gears, the driveline can match the power requirements of the vehicle or machinery to the load and torque demands, optimizing power delivery and efficiency.

5. Differential Systems:

In drivelines for vehicles with multiple driven wheels, such as cars with rear-wheel drive or all-wheel drive, differential systems are employed. Differentials distribute torque between the driven wheels while allowing them to rotate at different speeds, particularly during turns. This capability helps handle variations in load and torque between the wheels, ensuring smooth operation and minimizing tire wear.

6. Control Systems:

Modern drivelines often incorporate control systems that monitor and adjust power distribution based on various inputs, including load and torque conditions. These control systems, such as electronic control units (ECUs), can optimize power delivery, manage gear shifts, and adjust torque output to handle variations in load and torque. They may also incorporate sensors and feedback mechanisms to continuously monitor driveline performance and make real-time adjustments.

7. Overload Protection Mechanisms:

Some driveline systems include overload protection mechanisms to safeguard against excessive load or torque. These mechanisms can include torque limiters, shear pins, or safety clutches that disengage or slip when the load or torque exceeds a certain threshold. By providing a fail-safe mechanism, drivelines can protect the components from damage due to sudden or excessive variations in load and torque.

By incorporating these components and mechanisms, drivelines are capable of handling variations in load and torque during operation. They optimize power transmission, ensure smooth operation, and protect the driveline components from excessive stress or damage, ultimately enhancing the performance and longevity of the driveline system.

Are there any limitations or disadvantages associated with driveline systems?

While driveline systems offer numerous advantages in terms of power transmission and vehicle performance, there are also some limitations and disadvantages associated with their use. It’s important to consider these factors when designing, operating, and maintaining driveline systems. Let’s explore some of the limitations and disadvantages:

1. Complex Design and Integration:

Driveline systems can be complex in design, especially in modern vehicles with advanced technologies. They often consist of multiple components, such as transmissions, differentials, transfer cases, and drive shafts, which need to be properly integrated and synchronized. The complexity of the driveline system can increase manufacturing and assembly challenges, as well as the potential for compatibility issues or failures if not designed and integrated correctly.

2. Energy Losses:

Driveline systems can experience energy losses during power transmission. These losses occur due to factors such as friction, heat generation, mechanical inefficiencies, and fluid drag in components like gearboxes, differentials, and torque converters. The energy losses can negatively impact overall efficiency and result in reduced fuel economy or power output, especially in systems with multiple driveline components.

3. Limited Service Life and Maintenance Requirements:

Driveline components, like any mechanical system, have a limited service life and require regular maintenance. Components such as clutches, bearings, gears, and drive shafts are subject to wear and tear, and may need to be replaced or repaired over time. Regular maintenance, including lubrication, adjustments, and inspections, is necessary to ensure optimal performance and prevent premature failures. Failure to perform proper maintenance can lead to driveline malfunctions, increased downtime, and costly repairs.

4. Weight and Space Constraints:

Driveline systems add weight and occupy space within a vehicle. The additional weight affects fuel efficiency and overall vehicle performance. Moreover, the space occupied by driveline components can limit design flexibility, particularly in compact or electric vehicles where space optimization is crucial. Manufacturers must strike a balance between driveline performance, vehicle weight, and available space to meet the requirements of each specific vehicle type.

5. Noise, Vibration, and Harshness (NVH):

Driveline systems can generate noise, vibration, and harshness (NVH) during operation. Factors such as gear meshing, unbalanced rotating components, or improper driveline alignment can contribute to unwanted vibrations or noise. NVH issues can affect driving comfort, passenger experience, and vehicle refinement. Manufacturers employ various techniques, including vibration dampening materials, isolators, and precision engineering, to minimize NVH levels, but achieving complete elimination can be challenging.

6. Limited Torque Handling Capability:

Driveline systems have limitations in terms of torque handling capability. Excessive torque beyond the rated capacity of driveline components can lead to failures, such as shearing of gears, clutch slippage, or drive shaft breakage. High-performance vehicles or heavy-duty applications may require specialized driveline components capable of handling higher torque loads, which can increase costs and complexity.

7. Traction Limitations:

Driveline systems, particularly in vehicles with two-wheel drive configurations, may experience traction limitations, especially in slippery or off-road conditions. Power is typically transmitted to only one or two wheels, which can result in reduced traction and potential wheel slippage. This limitation can be mitigated by utilizing technologies such as limited-slip differentials, electronic traction control, or implementing all-wheel drive systems.

While driveline systems provide crucial power transmission and vehicle control, they do have limitations and disadvantages that need to be considered. Manufacturers, designers, and operators should carefully assess these factors and implement appropriate design, maintenance, and operational practices to optimize driveline performance, reliability, and overall vehicle functionality.

What benefits do drivelines offer for different types of vehicles and equipment?

Drivelines offer several benefits for different types of vehicles and equipment across various industries. They play a critical role in power transmission, mobility, efficiency, and overall performance. Here’s a detailed explanation of the benefits drivelines offer for different types of vehicles and equipment:

1. Power Transmission: Drivelines are designed to efficiently transmit power from the engine or power source to the driven components, such as wheels, tracks, implements, or machinery. They ensure the smooth transfer of torque, allowing vehicles and equipment to generate the necessary power for propulsion, lifting, hauling, or other tasks. By effectively transmitting power, drivelines maximize the performance and productivity of vehicles and equipment.

2. Mobility and Maneuverability: Drivelines enable vehicles and equipment to achieve mobility and maneuverability across various terrains and working conditions. By transmitting power to the wheels or tracks, drivelines provide the necessary traction and control to overcome obstacles, navigate uneven surfaces, and operate in challenging environments. They contribute to the overall stability, handling, and agility of vehicles and equipment, allowing them to move efficiently and safely.

3. Versatility and Adaptability: Drivelines offer versatility and adaptability for different types of vehicles and equipment. They can be designed and configured to meet specific requirements, such as front-wheel drive, rear-wheel drive, four-wheel drive, or all-wheel drive systems. This flexibility allows vehicles and equipment to adapt to various operating conditions, including normal roads, off-road terrains, agricultural fields, construction sites, or industrial facilities. Drivelines also accommodate different power sources, such as internal combustion engines, electric motors, or hybrid systems, enhancing the adaptability of vehicles and equipment.

4. Efficiency and Fuel Economy: Drivelines contribute to efficiency and fuel economy in vehicles and equipment. They optimize power transmission by utilizing appropriate gear ratios, minimizing energy losses, and improving overall system efficiency. Drivelines with advanced technologies, such as continuously variable transmissions (CVTs) or automated manual transmissions (AMTs), can further enhance efficiency by continuously adjusting gear ratios based on load and speed conditions. Efficient driveline systems help reduce fuel consumption, lower emissions, and maximize the operational range of vehicles and equipment.

5. Load Carrying Capacity: Drivelines are designed to handle and transmit high torque and power, enabling vehicles and equipment to carry heavy loads. They incorporate robust components, such as heavy-duty axles, reinforced drive shafts, and durable differentials, to withstand the demands of load-bearing applications. Drivelines ensure the reliable transmission of power, allowing vehicles and equipment to transport materials, tow trailers, or carry payloads efficiently and safely.

6. Safety and Control: Drivelines contribute to safety and control in vehicles and equipment. They enable precise control over acceleration, deceleration, and speed, enhancing driver or operator confidence and maneuverability. Drivelines with features like traction control systems, limited-slip differentials, or electronic stability control provide additional safety measures by improving traction, stability, and handling in challenging road or operating conditions. By ensuring optimal power distribution and control, drivelines enhance the overall safety and stability of vehicles and equipment.

7. Durability and Reliability: Drivelines are built to withstand harsh operating conditions and provide long-term durability and reliability. They are engineered with high-quality materials, precise manufacturing processes, and advanced technologies to ensure the driveline components can endure the stresses of power transmission. Well-designed drivelines require minimal maintenance, reducing downtime and enhancing the overall reliability of vehicles and equipment.

8. Specialized Functionality: Drivelines offer specialized functionality for specific types of vehicles and equipment. For example, in off-road vehicles or heavy-duty construction equipment, drivelines with features like differential locks, torque vectoring, or adjustable suspension systems provide enhanced traction, stability, and control. In agricultural machinery, drivelines with power take-off (PTO) units enable the connection of various implements for specific tasks like plowing, seeding, or harvesting. Such specialized driveline features enhance the performance and versatility of vehicles and equipment in their respective applications.

In summary, drivelines provide numerous benefits for different types of vehicles and equipment. They ensure efficient power transmission, facilitate mobility and maneuverability, offer versatility and adaptability, contribute to efficiency and fuel economy, handle heavy loads, enhance safety and control, provide durability and reliability, and offer specialized functionality. By incorporating well-designed drivelines, manufacturers can optimize the performance, productivity, and overall functionality of vehicles and equipment across various industries.

editor by CX 2024-05-17

China 150cc Motorcycle Transmission Gearbox Shaft Gear for Honda CBF150 CARGO150 with Hot selling

Error:获取session失败,

What is a drive shaft?

If you notice a clicking noise while driving, it is most likely the driveshaft. An experienced auto mechanic will be able to tell you if the noise is coming from both sides or from one side. If it only happens on one side, you should check it. If you notice noise on both sides, you should contact a mechanic. In either case, a replacement driveshaft should be easy to find.

The drive shaft is a mechanical part

A driveshaft is a mechanical device that transmits rotation and torque from the engine to the wheels of the vehicle. This component is essential to the operation of any driveline, as the mechanical power from the engine is transmitted to the PTO (power take-off) shaft, which hydraulically transmits that power to connected equipment. Different drive shafts contain different combinations of joints to compensate for changes in shaft length and angle. Some types of drive shafts include connecting shafts, internal constant velocity joints, and external fixed joints. They also contain anti-lock system rings and torsional dampers to prevent overloading the axle or causing the wheels to lock.

Although driveshafts are relatively light, they need to handle a lot of torque. Torque applied to the drive shaft produces torsional and shear stresses. Because they have to withstand torque, these shafts are designed to be lightweight and have little inertia or weight. Therefore, they usually have a joint, coupling or rod between the two parts. Components can also be bent to accommodate changes in the distance between them.

The drive shaft can be made from a variety of materials. The most common material for these components is steel, although alloy steels are often used for high-strength applications. Alloy steel, chromium or vanadium are other materials that can be used. The type of material used depends on the application and size of the component. In many cases, metal driveshafts are the most durable and cheapest option. Plastic shafts are used for light duty applications and have different torque levels than metal shafts.

It transfers power from the engine to the wheels

A car’s powertrain consists of an electric motor, transmission, and differential. Each section performs a specific job. In a rear-wheel drive vehicle, the power generated by the engine is transmitted to the rear tires. This arrangement improves braking and handling. The differential controls how much power each wheel receives. The torque of the engine is transferred to the wheels according to its speed.

The transmission transfers power from the engine to the wheels. It is also called “transgender”. Its job is to ensure power is delivered to the wheels. Electric cars cannot drive themselves and require a gearbox to drive forward. It also controls how much power reaches the wheels at any given moment. The transmission is the last part of the power transmission chain. Despite its many names, the transmission is the most complex component of a car’s powertrain.

The driveshaft is a long steel tube that transmits mechanical power from the transmission to the wheels. Cardan joints connect to the drive shaft and provide flexible pivot points. The differential assembly is mounted on the drive shaft, allowing the wheels to turn at different speeds. The differential allows the wheels to turn at different speeds and is very important when cornering. Axles are also important to the performance of the car.

It has a rubber boot that protects it from dust and moisture

To keep this boot in good condition, you should clean it with cold water and a rag. Never place it in the dryer or in direct sunlight. Heat can deteriorate the rubber and cause it to shrink or crack. To prolong the life of your rubber boots, apply rubber conditioner to them regularly. Indigenous peoples in the Amazon region collect latex sap from the bark of rubber trees. Then they put their feet on the fire to solidify the sap.

it has a U-shaped connector

The drive shaft has a U-joint that transfers rotational energy from the engine to the axle. Defective gimbal joints can cause vibrations when the vehicle is in motion. This vibration is often mistaken for a wheel balance problem. Wheel balance problems can cause the vehicle to vibrate while driving, while a U-joint failure can cause the vehicle to vibrate when decelerating and accelerating, and stop when the vehicle is stopped.

The drive shaft is connected to the transmission and differential using a U-joint. It allows for small changes in position between the two components. This prevents the differential and transmission from remaining perfectly aligned. The U-joint also allows the drive shaft to be connected unconstrained, allowing the vehicle to move. Its main purpose is to transmit electricity. Of all types of elastic couplings, U-joints are the oldest.

Your vehicle’s U-joints should be inspected at least twice a year, and the joints should be greased. When checking the U-joint, you should hear a dull sound when changing gears. A clicking sound indicates insufficient grease in the bearing. If you hear or feel vibrations when shifting gears, you may need to service the bearings to prolong their life.

it has a slide-in tube

The telescopic design is a modern alternative to traditional driveshaft designs. This innovative design is based on an unconventional design philosophy that combines advances in material science and manufacturing processes. Therefore, they are more efficient and lighter than conventional designs. Slide-in tubes are a simple and efficient design solution for any vehicle application. Here are some of its benefits. Read on to learn why this type of shaft is ideal for many applications.

The telescopic drive shaft is an important part of the traditional automobile transmission system. These driveshafts allow linear motion of the two components, transmitting torque and rotation throughout the vehicle’s driveline. They also absorb energy if the vehicle collides. Often referred to as foldable driveshafts, their popularity is directly dependent on the evolution of the automotive industry.

It uses a bearing press to replace worn or damaged U-joints

A bearing press is a device that uses a rotary press mechanism to install or remove worn or damaged U-joints from a drive shaft. With this tool, you can replace worn or damaged U-joints in your car with relative ease. The first step involves placing the drive shaft in the vise. Then, use the 11/16″ socket to press the other cup in far enough to install the clips. If the cups don’t fit, you can use a bearing press to remove them and repeat the process. After removing the U-joint, use a grease nipple Make sure the new grease nipple is installed correctly.

Worn or damaged U-joints are a major source of driveshaft failure. If one of them were damaged or damaged, the entire driveshaft could dislocate and the car would lose power. Unless you have a professional mechanic doing the repairs, you will have to replace the entire driveshaft. Fortunately, there are many ways to do this yourself.

If any of these warning signs appear on your vehicle, you should consider replacing the damaged or worn U-joint. Common symptoms of damaged U-joints include rattling or periodic squeaking when moving, rattling when shifting, wobbling when turning, or rusted oil seals. If you notice any of these symptoms, take your vehicle to a qualified mechanic for a full inspection. Neglecting to replace a worn or damaged u-joint on the driveshaft can result in expensive and dangerous repairs and can cause significant damage to your vehicle.

editor by Cx 2023-04-26

China China Gearbox Parts Drive Shaft Me636001 6D16 for Mitsubishi with Hot selling

Merchandise Description

Merchandise PARAMETER

| China Gearbox components Push Shaft ME636001 6D16 For MITSUBISHI | ||||||

|

Portion identify |

Transmission shaft equipment | |||||

|

Guarantee |

1 Calendar year |

|||||

|

HS Code |

8708457100 |

|||||

|

Packing |

Carton Box with Brand / Nature Packing |

|||||

Business Info

HangZhou CZPT Imp.& Exp.Co .,Ltd located in HangZhou,ZHangZhoug Province. Have been committed to developing & supplying Auto Transmission Components,placing ourselves to clients’ sneakers to fix their calls for.our business is mostly engaged in Automobile Transmission Elements these kinds of as Transmission gearbox,Gear haft,Synchronizer ring,Cylinder Head and Differcial Assembly and so on.

With our honesty and credit score, we sincerely hope to cooperate with you for higher growth. Welcome new and outdated buyers from all walks of daily life to get in touch with us for potential enterprise relationships and obtaining mutual good results!

Entire world-Extensive Customers Responses & FEEDBACK

Listed here is some of comments from our entire world-broad buyers.

You can check all the comments at our business profile.

You should go to tashikomo

Click on “business profile”,then pick “Rating & Reviews”

(remember to observe: all our customer feedback is actual 1………..)

We will package the product meticulously and deliver it by means of EMS,DHL,or other individuals…..

Contact

FAQ

★ What is your conditions of packing?

A: Typically, we pack our merchandise in neutral white packing containers and brown cartons. If you have lawfully registered patent,

we can pack the merchandise in your branded packing containers right after receiving your authorization letters.

★ What is your phrases of payment?

A: T/T 30% as deposit, and 70% before supply. We will show you the photos of the goods and deals

ahead of you shell out the equilibrium.

★Can you generate according to the samples?

A: Sure, we can create by your samples or technical drawings. We can develop the molds and fixtures.

Motion now make contact with us for complete CATALOG.

Much more THEN 2000 Types OF OEM Components WAITTING FOR YHOU. Please Contact US THE Complete CATALOG.

Believe in YOU WILL LIKE OUR Types & PRICE.

You should contat us for the Total CATALOG. A lot more than 2000 OEM Components.

WAITTING FOR YOU !!

Motion NOW

|

US $2.8-15 / Piece | |

5 Pieces (Min. Order) |

###

| Warranty: | 1 Year |

|---|---|

| Type: | Shaft Gear |

| Material: | 20crmnti |

| Certification: | ISO |

| Automatic: | Manual |

| Standard: | Standard |

###

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| China Gearbox parts Drive Shaft ME636001 6D16 For MITSUBISHI | ||||||

|

Part name

|

Transmission shaft gear | |||||

|

Warranty

|

1 Year

|

|||||

|

HS Code

|

8708402000

|

|||||

|

Packing

|

Carton Box with Brand / Nature Packing

|

|||||

|

US $2.8-15 / Piece | |

5 Pieces (Min. Order) |

###

| Warranty: | 1 Year |

|---|---|

| Type: | Shaft Gear |

| Material: | 20crmnti |

| Certification: | ISO |

| Automatic: | Manual |

| Standard: | Standard |

###

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| China Gearbox parts Drive Shaft ME636001 6D16 For MITSUBISHI | ||||||

|

Part name

|

Transmission shaft gear | |||||

|

Warranty

|

1 Year

|

|||||

|

HS Code

|

8708402000

|

|||||

|

Packing

|

Carton Box with Brand / Nature Packing

|

|||||

Driveshaft structure and vibrations associated with it

The structure of the drive shaft is critical to its efficiency and reliability. Drive shafts typically contain claw couplings, rag joints and universal joints. Other drive shafts have prismatic or splined joints. Learn about the different types of drive shafts and how they work. If you want to know the vibrations associated with them, read on. But first, let’s define what a driveshaft is.

transmission shaft

As the demand on our vehicles continues to increase, so does the demand on our drive systems. Higher CO2 emission standards and stricter emission standards increase the stress on the drive system while improving comfort and shortening the turning radius. These and other negative effects can place significant stress and wear on components, which can lead to driveshaft failure and increase vehicle safety risks. Therefore, the drive shaft must be inspected and replaced regularly.

Depending on your model, you may only need to replace one driveshaft. However, the cost to replace both driveshafts ranges from $650 to $1850. Additionally, you may incur labor costs ranging from $140 to $250. The labor price will depend on your car model and its drivetrain type. In general, however, the cost of replacing a driveshaft ranges from $470 to $1850.

Regionally, the automotive driveshaft market can be divided into four major markets: North America, Europe, Asia Pacific, and Rest of the World. North America is expected to dominate the market, while Europe and Asia Pacific are expected to grow the fastest. Furthermore, the market is expected to grow at the highest rate in the future, driven by economic growth in the Asia Pacific region. Furthermore, most of the vehicles sold globally are produced in these regions.

The most important feature of the driveshaft is to transfer the power of the engine to useful work. Drive shafts are also known as propeller shafts and cardan shafts. In a vehicle, a propshaft transfers torque from the engine, transmission, and differential to the front or rear wheels, or both. Due to the complexity of driveshaft assemblies, they are critical to vehicle safety. In addition to transmitting torque from the engine, they must also compensate for deflection, angular changes and length changes.

type

Different types of drive shafts include helical shafts, gear shafts, worm shafts, planetary shafts and synchronous shafts. Radial protruding pins on the head provide a rotationally secure connection. At least one bearing has a groove extending along its circumferential length that allows the pin to pass through the bearing. There can also be two flanges on each end of the shaft. Depending on the application, the shaft can be installed in the most convenient location to function.

Propeller shafts are usually made of high-quality steel with high specific strength and modulus. However, they can also be made from advanced composite materials such as carbon fiber, Kevlar and fiberglass. Another type of propeller shaft is made of thermoplastic polyamide, which is stiff and has a high strength-to-weight ratio. Both drive shafts and screw shafts are used to drive cars, ships and motorcycles.

Sliding and tubular yokes are common components of drive shafts. By design, their angles must be equal or intersect to provide the correct angle of operation. Unless the working angles are equal, the shaft vibrates twice per revolution, causing torsional vibrations. The best way to avoid this is to make sure the two yokes are properly aligned. Crucially, these components have the same working angle to ensure smooth power flow.

The type of drive shaft varies according to the type of motor. Some are geared, while others are non-geared. In some cases, the drive shaft is fixed and the motor can rotate and steer. Alternatively, a flexible shaft can be used to control the speed and direction of the drive. In some applications where linear power transmission is not possible, flexible shafts are a useful option. For example, flexible shafts can be used in portable devices.

put up

The construction of the drive shaft has many advantages over bare metal. A shaft that is flexible in multiple directions is easier to maintain than a shaft that is rigid in other directions. The shaft body and coupling flange can be made of different materials, and the flange can be made of a different material than the main shaft body. For example, the coupling flange can be made of steel. The main shaft body is preferably flared on at least one end, and the at least one coupling flange includes a first generally frustoconical projection extending into the flared end of the main shaft body.

The normal stiffness of fiber-based shafts is achieved by the orientation of parallel fibers along the length of the shaft. However, the bending stiffness of this shaft is reduced due to the change in fiber orientation. Since the fibers continue to travel in the same direction from the first end to the second end, the reinforcement that increases the torsional stiffness of the shaft is not affected. In contrast, a fiber-based shaft is also flexible because it uses ribs that are approximately 90 degrees from the centerline of the shaft.

In addition to the helical ribs, the drive shaft 100 may also contain reinforcing elements. These reinforcing elements maintain the structural integrity of the shaft. These reinforcing elements are called helical ribs. They have ribs on both the outer and inner surfaces. This is to prevent shaft breakage. These elements can also be shaped to be flexible enough to accommodate some of the forces generated by the drive. Shafts can be designed using these methods and made into worm-like drive shafts.

vibration

The most common cause of drive shaft vibration is improper installation. There are five common types of driveshaft vibration, each related to installation parameters. To prevent this from happening, you should understand what causes these vibrations and how to fix them. The most common types of vibration are listed below. This article describes some common drive shaft vibration solutions. It may also be beneficial to consider the advice of a professional vibration technician for drive shaft vibration control.

If you’re not sure if the problem is the driveshaft or the engine, try turning on the stereo. Thicker carpet kits can also mask vibrations. Nonetheless, you should contact an expert as soon as possible. If vibration persists after vibration-related repairs, the driveshaft needs to be replaced. If the driveshaft is still under warranty, you can repair it yourself.

CV joints are the most common cause of third-order driveshaft vibration. If they are binding or fail, they need to be replaced. Alternatively, your CV joints may just be misaligned. If it is loose, you can check the CV connector. Another common cause of drive shaft vibration is improper assembly. Improper alignment of the yokes on both ends of the shaft can cause them to vibrate.

Incorrect trim height can also cause driveshaft vibration. Correct trim height is necessary to prevent drive shaft wobble. Whether your vehicle is new or old, you can perform some basic fixes to minimize problems. One of these solutions involves balancing the drive shaft. First, use the hose clamps to attach the weights to it. Next, attach an ounce of weight to it and spin it. By doing this, you minimize the frequency of vibration.

cost

The global driveshaft market is expected to exceed (xxx) million USD by 2028, growing at a compound annual growth rate (CAGR) of XX%. Its soaring growth can be attributed to several factors, including increasing urbanization and R&D investments by leading market players. The report also includes an in-depth analysis of key market trends and their impact on the industry. Additionally, the report provides a comprehensive regional analysis of the Driveshaft Market.

The cost of replacing the drive shaft depends on the type of repair required and the cause of the failure. Typical repair costs range from $300 to $750. Rear-wheel drive cars usually cost more. But front-wheel drive vehicles cost less than four-wheel drive vehicles. You may also choose to try repairing the driveshaft yourself. However, it is important to do your research and make sure you have the necessary tools and equipment to perform the job properly.

The report also covers the competitive landscape of the Drive Shafts market. It includes graphical representations, detailed statistics, management policies, and governance components. Additionally, it includes a detailed cost analysis. Additionally, the report presents views on the COVID-19 market and future trends. The report also provides valuable information to help you decide how to compete in your industry. When you buy a report like this, you are adding credibility to your work.

A quality driveshaft can improve your game by ensuring distance from the tee and improving responsiveness. The new material in the shaft construction is lighter, stronger and more responsive than ever before, so it is becoming a key part of the driver. And there are a variety of options to suit any budget. The main factor to consider when buying a shaft is its quality. However, it’s important to note that quality doesn’t come cheap and you should always choose an axle based on what your budget can handle.

editor by czh 2022-12-07

China Hot selling 6T55-3000B3 Good quality SINOTRUK HOWO truck parts truck gearbox parts Output driving shaft assy for heavy trucks drive shaft center bearing

Yr: 2005-, 2007-, -, 2006-

Product: Howo, Golden Prince, CZPT A7, STEYR KING

OE NO.: 6T55-3000B3

Auto Fitment: CZPT (CNHTC)

Variety: Gear Box

Dimensions: 55*20*fifteen cm

Product Variety: 6T55-3000B3

Truck Design: Howo

Solution Title: truck components Output driving shaft assy

Fat: 25kg

Port: HangZhou

Bundle: Plastic/ Carton/ wooden box/ Pallet

Shade: Customer Calls for

Provider: OEM& ODM

Guarantee: 3months

MOQ: 1set

High quality: one hundred%examined

Delivery: 5-7 Times

Packaging Information: Plastic/ Carton/ picket box/ Pallet

Port: HangZhou

Items Screen

| Truck Areas And Truck Accessories Name | truck components Output driving shaft assy |

| Truck Component-Model Amount | 6T55-3000B3 |

| Size | 55*20*fifteen cm |

| Weight | 25kg |

| MOQ | 1 pcs/established |

| Supply Capability | 10000 Established/Sets for every working day |

| Warranty | 3 months |

| Price | Send inquiry to get the newest price |

| Package | Plastic/ Carton/ wood box/ Pallet |

| Delivery Time | 3-5 days with inventory and twenty-50 working day for Customized |

| Color | Customer Calls for |

| Service | We accept OEM&ODM . |

What is a driveshaft and how much does it cost to replace one?

Your vehicle is made up of many moving parts. Knowing each part is important because a damaged driveshaft can seriously damage other parts of the car. You may not know how important your driveshaft is, but it’s important to know if you want to fix your car. In this article, we’ll discuss what a driveshaft is, what its symptoms are, and how much it costs to replace a driveshaft.

Repair damaged driveshafts

A damaged driveshaft does not allow you to turn the wheels freely. It also exposes your vehicle to higher repair costs due to damaged driveshafts. If the drive shaft breaks while the car is in motion, it may cause a crash. Also, it can significantly affect the performance of the car. If you don’t fix the problem right away, you could risk more expensive repairs. If you suspect that the drive shaft is damaged, do the following.

First, make sure the drive shaft is protected from dust, moisture, and dust. A proper driveshaft cover will prevent grease from accumulating in the driveshaft, reducing the chance of further damage. The grease will also cushion the metal-to-metal contact in the constant velocity joints. For example, hitting a soft material is better than hitting a metal wall. A damaged prop shaft can not only cause difficult cornering, but it can also cause the vehicle to vibrate, which can further damage the rest of the drivetrain.

If the driveshaft is damaged, you can choose to fix it yourself or take it to a mechanic. Typically, driveshaft repairs cost around $200 to $300. Parts and labor may vary based on your vehicle type and type of repair. These parts can cost up to $600. However, if you don’t have a mechanical background, it’s better to leave it to a professional.

If you notice that one of the two drive shafts is worn, it’s time to repair it. Worn bushings and bearings can cause the drive shaft to vibrate unnecessarily, causing it to break and cause further damage. You can also check the center bearing if there is any play in the bearing. If these symptoms occur, it is best to take your car to a mechanic as soon as possible.

Learn about U-joints

While most vehicles have at least one type of U-joint, there are other types available. CV joints (also known as hot rod joints) are used in a variety of applications. The minor axis is shorter than the major axis on which the U-joint is located. In both cases, the U-joints are lubricated at the factory. During servicing, the drive shaft slip joint should be lubricated.

There are two main styles of U-joints, including forged and press fit. They are usually held in place by C-clamps. Some of these U-joints have knurls or grooves. When selecting the correct fitting, be sure to measure the entire fitting. To make sure you get the correct size, you can use the size chart or check the manual for your specific model.

In addition to lubrication, the condition of the U-joint should be checked regularly. Lubricate them regularly to avoid premature failure. If you hear a clicking sound when shifting gears, the u-joint space may be misaligned. In this case, the bearing may need to be serviced. If there is insufficient grease in the bearings, the universal joint may need to be replaced.

U-joint is an important part of the automobile transmission shaft. Without them, your car would have no wheeled suspension. Without them, your vehicle will have a rickety front end and a wobbly rear end. Because cars can’t drive on ultra-flat surfaces, they need flexible driveshafts. The U-joint compensates for this by allowing it to move up and down with the suspension.

A proper inspection will determine if your u-joints are loose or worn. It should be easy to pull them out. Make sure not to pull them all the way out. Also, the bearing caps should not move. Any signs of roughness or wear would indicate a need for a new UJ. Also, it is important to note that worn UJs cannot be repaired.

Symptoms of Driveshaft Failure

One of the most common problems associated with a faulty driveshaft is difficulty turning the wheels. This severely limits your overall control over the vehicle. Fortunately, there are several symptoms that could indicate that your driveshaft is failing. You should take immediate steps to determine the cause of the problem. One of the most common causes of driveshaft failure is a weak or faulty reverse gear. Other common causes of driveshaft damage include driving too hard, getting stuck in reverse gear and differential lock.

Another sign of a failed driveshaft is unusual noise while driving. These noises are usually the result of wear on the bushings and bearings that support the drive shaft. They can also cause your car to screech or scratch when switching from drive to idle. Depending on the speed, the noise may be accompanied by vibration. When this happens, it’s time to send your vehicle in for a driveshaft replacement.

One of the most common symptoms of driveshaft failure is noticeable jitter when accelerating. This could be a sign of a loose U-joint or worn center bearing. You should thoroughly inspect your car to determine the cause of these sounds and corresponding symptoms. A certified mechanic can help you determine the cause of the noise. A damaged propshaft can severely limit the drivability of the vehicle.

Regular inspection of the drive shaft can prevent serious damage. Depending on the damage, you can replace the driveshaft for anywhere from $500 to $1,000. Depending on the severity of the damage and the level of repair, the cost will depend on the number of parts that need to be replaced. Do not drive with a bad driveshaft as it can cause a serious crash. There are several ways to avoid this problem entirely.

The first symptom to look for is a worn U-joint. If the U-joint comes loose or moves too much when trying to turn the steering wheel, the driveshaft is faulty. If you see visible rust on the bearing cap seals, you can take your car to a mechanic for a thorough inspection. A worn u-joint can also indicate a problem with the transmission.

The cost of replacing the drive shaft

Depending on your state and service center, a driveshaft repair can cost as little as $300 or as high as $2,000, depending on the specifics of your car. Labor costs are usually around $70. Prices for the parts themselves range from $400 to $600. Labor costs also vary by model and vehicle make. Ultimately, the decision to repair or replace the driveshaft will depend on whether you need a quick car repair or a full car repair.

Some cars have two separate driveshafts. One goes to the front and the other goes to the back. If your car has four wheel drive, you will have two. If you’re replacing the axles of an all-wheel-drive car, you’ll need a special part for each axle. Choosing the wrong one can result in more expensive repairs. Before you start shopping, you should know exactly how much it will cost.

Depending on the type of vehicle you own, a driveshaft replacement will cost between PS250 and PS500. Luxury cars can cost as much as PS400. However, for safety and the overall performance of the car, replacing the driveshaft may be a necessary repair. The cost of replacing a driveshaft depends on how long your car has been on the road and how much wear and tear it has experienced. There are some symptoms that indicate a faulty drive shaft and you should take immediate action.

Repairs can be expensive, so it’s best to hire a mechanic with experience in the field. You’ll be spending hundreds of dollars a month, but you’ll have peace of mind knowing the job will be done right. Remember that you may want to ask a friend or family member to help you. Depending on the make and model of your car, replacing the driveshaft is more expensive than replacing the parts and doing it yourself.

If you suspect that your drive shaft is damaged, be sure to fix it as soon as possible. It is not advisable to drive a car with abnormal vibration and sound for a long time. Fortunately, there are some quick ways to fix the problem and avoid costly repairs later. If you’ve noticed the symptoms above, it’s worth getting the job done. There are many signs that your driveshaft may need service, including lack of power or difficulty moving the vehicle.

China manufacturer & factory supplier for XG in Rostov-on-Don Russian Federation Series Shaft Mounted gearbox speed reducer motor Pt A SERISI Saft Montajli Helisel Dislili Reductor Arm Shaft Mount Reducer With high quality best price & service

EPG aims at actively playing a foremost part in a industry which keeps building new competitors techniques with regard to top quality, economic system and presence. This goal is to be achieved by means of the joint help coming from all the company’s departments (Production dept., Specialized dept. and Product sales dept.) and a extremely experienced around the world distribution community.

Company of roller travel chains for electrical power transmission purposes from basic industrial to functions in specialised areas this kind of as foodstuff processing, large construction gear, and oil area providers. Offered in double pitch travel and common roller chains with one and a number of strand configurations. Specifications include .25 to 3 in. chain pitch, .13 to 1.88 in. length among sidebars, and .09 to .94 in. pin diameter. Offered with attributes this kind of as case-hardened and armor-cased pins, pre-pressured method, corrosion and shock resistance, and stainless metal resources. Supplies publish-sale assist providers.The new merchandise incorporate a series of high-tech and large high quality chains and sprockets and gears, these kinds of as chains and gearboxes for agricultural machineries, metallurgical chains, escalator stage-chains, higher-velocity tooth chains, timing chains, self-lubrication chains, among which have variety high pace tooth chain for automobile branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Rapid Specifics

- Relevant Industries:

-

Constructing Content Shops

- Gearing Arrangement:

-

Helical

-

PTO Shaft A PTO Adapter will be beneficial when operating Victory’s EMSD and EMHD Embankment Flail mowers. The absence of a PTO Adapter could trigger the PTO shaft to conflict with the arm weldment, which connects to the CAT I/II 3 stage hitch.

- Output Torque:

-

137~9800 N.m

- Input Speed:

-

1400rpm

- Output Velocity:

-

46~280RPM

- Location of Origin:Zhejiang, China

- Brand name Name:

-

OEM

- Colour:

-

Blue / Grey / Customer prerequisite

Provide Capability

- Offer Potential:

- 2000 Established/Sets per Month

Packaging & Delivery

- Packaging Particulars

- wooden Case per computer + many pcs in wood case

- Port

- Chinese Port

-

Guide Time

: -

Amount(Bins) one – one >1 Est. Time(days) twenty To be negotiated EPG is specialized in style, manufacturer and revenue of agricultural equipment and farm implements, which has an unbiased import and export rights.

Online Customization

XG Sequence Shaft Mounted gearbox velocity reducer motor Pt/A SERISI Saft Montajli Helisel Dislili Reductor Arm Shaft Mount Reducer

Solution Application

Conveyor & Material Managing

Mining & Quarry

SLXG Shaft Mounted Reducer | Output Shaft Bore [mm] | Ratio(i) | Rated torque |

SLXG30 | Φ30 | seven, 10, 12.five | 180N.m |

SLXG35 | Φ35 | five,ten,15,20,25 | 420N.m |

SLXG40 | Φ40 | 5,ten,twelve.5,15,20,25 | 900N.m |

Φ45 | |||

SLXG45 | Φ45 | five,ten,twelve.5,fifteen,20,25 | 1400N.m |

Φ50 | |||

Φ55 | |||

SLXG50 | Φ50 | 5,10,twelve.5,15,20,twenty five | 2300N.m |

Φ55 | |||

Φ60 | |||

SLXG60 | Φ60 | 5,10,12.5,15,twenty,twenty five | 3600N.m |

Φ70 | |||

SLXG70 | Φ70 | five,ten,12.5,fifteen,20,twenty five,31 | 5100N.m |

Φ85 | |||

SLXG80 | Φ80 | 5,10,12.5,15,20,twenty five,31 | 7000N.m |

Φ100 | |||

SLXG100 | Φ100 | 5,ten,twelve.5,fifteen,20,25,31 | 11000N.m |

Φ125 |

China manufacturer & factory supplier for 2-900N.m in Djibouti Djibouti Output Torque ZLYJ type Parallel Shaft Extruder Gearbox Reducer With high quality best price & service

As a consequence, we have grow to be a comprehensive manufacturer in the movement and handle subject offering an in depth lineup of goods with excellent longevity, atmosphere-friendliness, and good quality.Excellent attention has been compensated on environmental protection and vitality saving.

Overview

Fast Particulars

- Relevant Industries:

-

These are compact, large-responsibility drives that supply prolonged-existence overall performance functions and simplified routine maintenance. They consist of double and triple reduction units. They are available in a range of configurations for maximum positioning overall flexibility. They provide very good toughness and longevity. The large toughness output shaft assures potential for high torque and overhung hundreds.

Creating Substance Stores, Manufacturing Plant, Equipment Repair Shops, Farms, Building works , Meals & Beverage Retailers

- Spot of Origin:Zhejiang, China

- Gearing Arrangement:

-

Helical

- Output Torque:

-

2-900N.m

- Input Pace:

-

750-1500rpm

Our organization has solid financial energy, builds up a technician team contingent with high high quality, possesses the manufacturing assembly line of technicalization in China and ideal technique checking on solution high quality and operates marketing and advertising networks all through the region.

- Output Speed:

-

21-1200rpm

- Ratio:

-

up to twenty

- Certificates:

-

CE,ISO9001

- Warranty:

-

1 Yr

- Warmth treatment:

-

High Frequency Quenching

In our company we are conscious of the significance of the users’ protection. That is why our PTO’s are produced in accordance to lawful rules and European directives and bear the CE sign. A essential issue for security assurance is the accession in the products’ growth period. By all means, the users’ information about the proper use of a PTO travel shaft is crucial. This implies, that every single users’ duty is to read through and follow the safety instructions.

- Keyword:

-

ZLYJ extruder

- Enter Sort:

-

Thrust structure

Provide Capacity

- Source Capacity:

- 5000 Piece/Pieces per Yr

Packaging & Shipping

- Packaging Specifics

- wooden circumstances

- Port

- Ningbo,Shanghai

-

Lead Time

: -

Amount(Bins) 1 – one >1 Est. Time(days) 15 To be negotiated

Online Customization

Item Description

one.The gears are carburized, quenched and ground. Gear precision gb10095-88,

two.Six-amount tough equipment, hardness HRC54~sixty two.

three.The front component of the hollow output shaft is geared up with a big thrust bearing, which can bear the axial thrust when the screw is doing work.

four. little dimension, huge bearing capability and stable procedure.

5.Transmission, reduced noise and high effectiveness.

Related Merchandise

Firm Details

Ever-Energy Team CO., LTD. IS Expert IN Making ALL Kinds OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Gear Pace REDUCERS, PARALLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Vehicle GEARBOXES, PTO Generate SHAFTS, Specific REDUCER & Connected Gear Elements AND OTHER Related Merchandise, SPROCKETS, HYDRAULIC Program, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Pace VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Equipment PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Lower BACKLASH WORM REDUCERS AND SO ON. Moreover, WE CAN Produce Customized VARIATORS, GEARED MOTORS, Electric powered MOTORS AND OTHER HYDRAULIC Goods According TO CUSTOMERS’ DRAWINGS.

Certifications

Product packaging

China manufacturer & factory supplier for china in Kerman Iran manufacturer BAB042 High efficiency low backlash precision planetary reducer gearbox With high quality best price & service

ISO 9001 certified company of precision roller chains. Kinds include solitary and numerous strand, hollow pin, aspect bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains. The team is concentrated on creating all assortment of standard roller chains and sprockets, gears & gearboxes, such as conveyor chain & sprockets , stainless steel chain, agricultural chain and has not just bought its merchandise all above china, but also offered much more than 65% items to oversees, such as Europe, America, South-east Asia, and it also has set up storage logistics in places like Europe.

Overview

Swift Particulars

- AppEPG model rotocultivator ploughshares in T. line ended up picked as the Nationwide Rotary Tillage Equipment Industry “Best Brand Items” in 2007 by Rotocultivator Branch of China Agricultural Machinery Market Affiliation. licable Industries:

-

CNC

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

14~22 N.m

- Enter Velocity:

-

5000rpm

- Output Velocity:

-

*

- Area of Origin:Zhejiang, China

- Manufacturer Title:

-

OEM

- Merchandise name:

-

precision planetary gearbox

- Substance:

-

20CrMnTi, 40Cr

- Ratio:

-

3-10

- Backlash:

-

P2

- Ingress security:

-

IP65

- Colour:

-

champagne gold+black/ silver+blue/ OEM colour

- Heat treatment method:

-

sizzling forged/hardening

Supply Potential

- Provide Capability:

- 200000 Piece/Pieces for every Month

Packaging & Shipping

- Port

- Ningbo/Shanghai/ China Port

-

Guide Time

: -

Amount(Items) one – a thousand >1000 Est. Time(times) 30 To be negotiated

On the web Customization

Ever-power Group Co., Ltd. is Specialist IN Creating ALL Types OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Speed REDUCERS, PARALLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Automobile GEARBOXES, PTO Generate SHAFTS, Specific REDUCER & Related Equipment Factors AND OTHER Connected Goods, SPROCKETS, HYDRAULIC System, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Speed VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Low BACKLASH WORM REDUCERS AND SO ON. Furthermore, WE CAN Generate Personalized VARIATORS, GEARED MOTORS, Electric powered MOTORS AND OTHER HYDRAULIC Goods According TO Clients DRAWINGS.

HangZhou At any time-PowerMechanical & Electrical Co., Ltd. is a specialist maker ofgearbox and motors.The factory covers an region of 20,000 sq. meters, the constructing spot of 30,000 square meters, the complete variety of workers is much more than 200 .We have passed theISO9001:2015global qWorm gears are normally manufactured by hobbing with a hob or reducing resource really equivalent to the worm that the equipment mates with. The worm might be turned, hobbed, milled, or floor.uality management method normal certification,CCCnational compulsory product certification andCEcertification . We have produced sophisticated administration computer software such asERPto hold speed with intercontinental regular.In get to provide customers far better the organization actively cooperates with schools and universities to create new goods and improve existing products .

|

Q1. Are you investing company or manufacturer? A. We are manufacturer Located in Taizhou Town of East China. Q2. How is ensure of the top quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled examine and file material and semi-finished spare areas. And – 100% inspect completed spare parts prior to place in storage. – 100% examine ahead of assembly. – one hundred% examine just before packaging. Q3. What information shall we give just before placing a acquire purchase? We can source technological assist and the drawing according to your prerequisite if you speak to with me. This autumn. What industries are your gearboxes currently being employed? Our gearboxes are widely utilized in the regions of textile, meals processing, beverage, chemical market,escalator,automated storage tools, metallurgy, tabacco, environmental protection, logistics and and so on. Q5. Do you have guarantee services? Indeed, the Near up of two yokes with the universal joint. Notice the slight oozing of grease from the UJ seal ends, the clump of grease is from within the yoke splined shaft location –Generate (outer) yoke has a woman (typical spline) gap and “Y” form end that is the common joint (UJ) mount. –UJ is a cross formed casting possessing roller bearings enclosed with caps at all four factors and is held into the yoke with 4 “C” clips –Internal yoke and push shaft is another yoke welded to the generate conclude, of the generate shaft. –Driven shaft and interior yoke is the driven shaft that rides within of the generate shaft and has a yoke welded at the pushed stop –UJ an additional UJ as abovegearbox is free of charge warranty inside 1 several years following shipping. |

||||||

China manufacturer & factory supplier for Sell in Nnewi Nigeria well in India worm gear speed reduction NMRV150 RV150 NMRV 150 gearbox nmrv series small reductor with electric motor With high quality best price & service

EP Team has elevated its business traces to incorporate Energy Transmission Models and Factors, Automotive Parts and Components Handling Techniques.Full use has been manufactured of all varieties of superior tactics and technologies to reach excelsior producing.

Overview

Quick Particulars

- Applicable Industries:

-

Producing Plant

- Place of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

- Item NO:

-

SYF

- Rated Energy:

-

.06-15KW

- Item Keywords and phrases:

-

rv gearbox

- Colour:

-

Blue

- Item title:

-

Worm Gear Screw Jack

- Application:

-

Mining Plant

- Materials:

-

Aluminium Alloy

- Bearing:

-

NSK

- Certificate:

-

ISO9001

- Ratio:

-

five-one hundred

It was born in 1997, and is the fruit of the merger of various gearboxes brand names. From the 1st goods, it inherited a philosophy dependent in top quality, profitability and technological rigor. EPG is current in all european industry, by way of a comprehensive distribution chain consisting of every market’s principal actors.

Packaging & Supply

-

Guide Time

: -

Amount(Parts) 1 – a hundred >100 Est. Time(times) 20 To be negotiated

Online Customization

Item Description

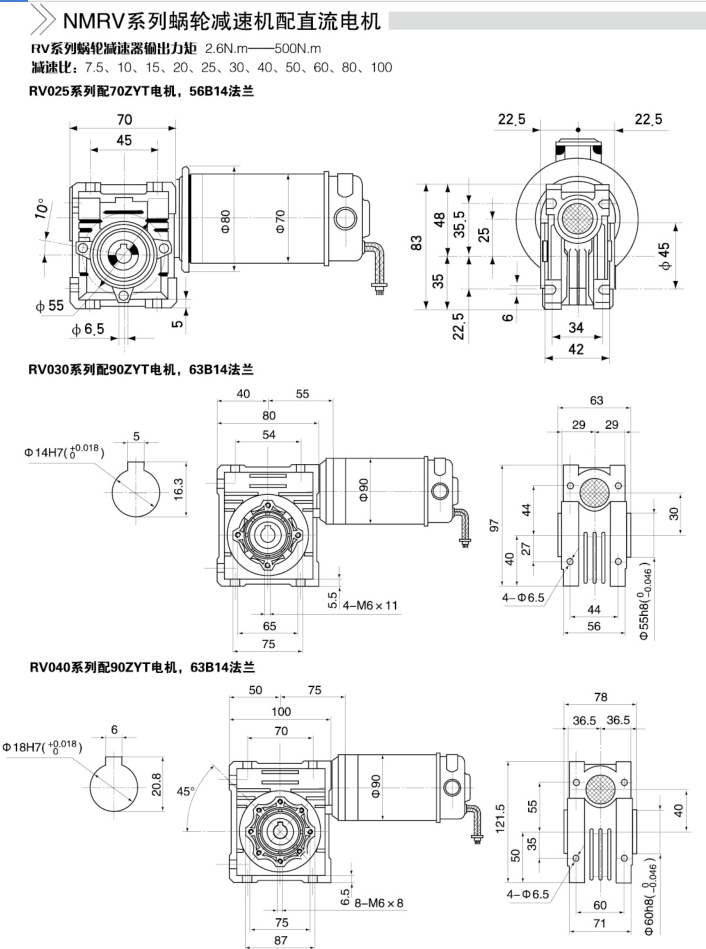

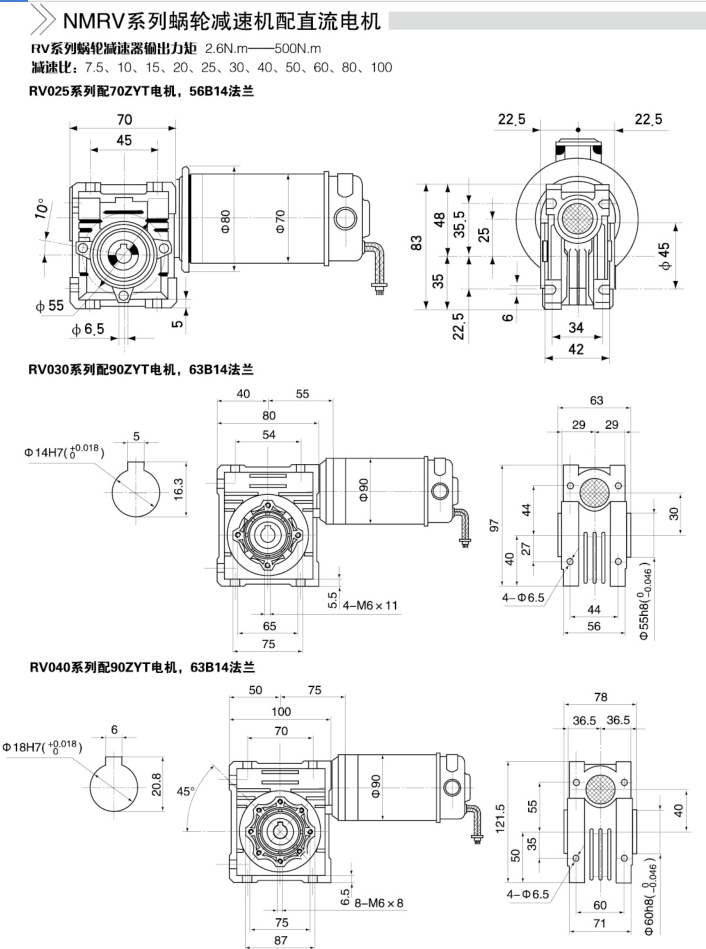

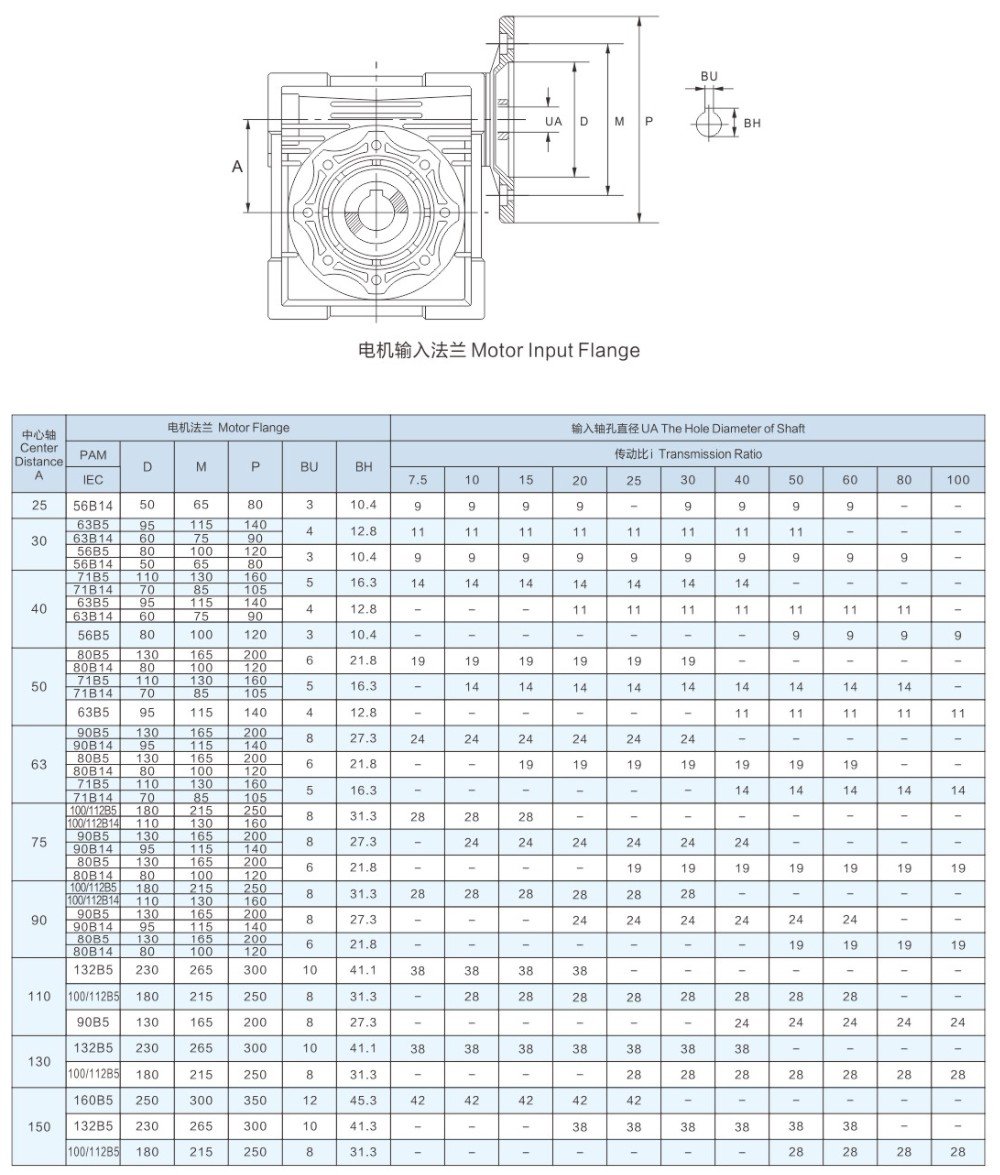

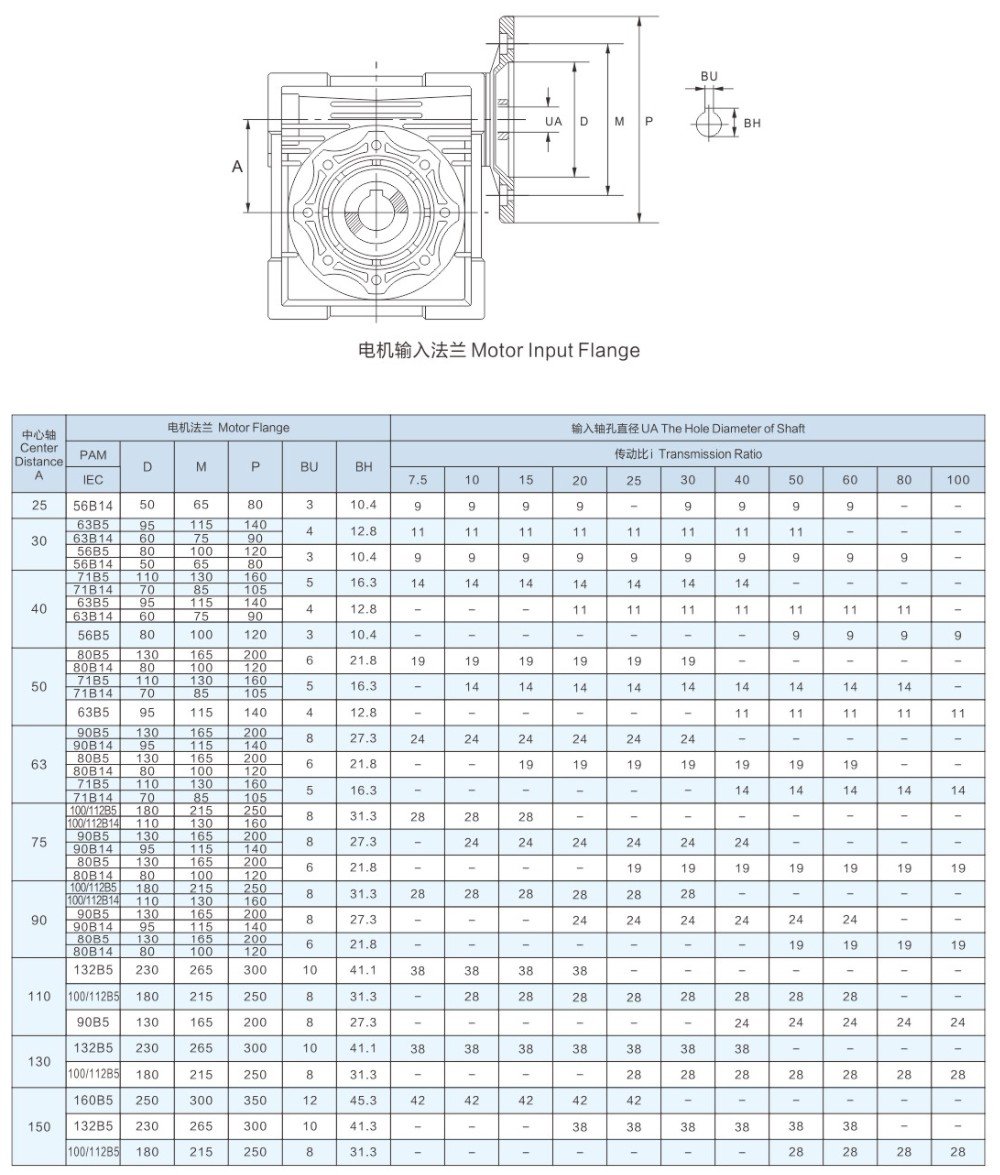

NMRV WORM Gear Speed REDUCER WITH ZYT Series DC MOTOR

In accordance to European common of similar product,we adopt large-good quality synthetic oil,imported well-known brand seal areas and manufacture technological innovation to produce sq. multi-placed reductor. Function lovely appearance,straightforward set up,compact composition,low sounds and substantial efficiency.

NMRV worm equipment reducer absorbs advanced technology at residence and abroad. It has a novel and distinctive “sq. box” external composition. The box is stunning in condition and is made of high good quality aluminium alloy by die casting.

NMRV series construction drawing

|

Worm Gear Velocity Reducer NMRV+DC Motor Sizzling Offering Level |

||

|

Offering level 1 |

The primary function is that it has reverse self-locking operate, Suitable for all-spherical installation. |

|

|

Promoting position 2 |

Small dimension, gentle fat, low sounds, lengthy support daily life. |

|

|

Marketing point 3 |

Utilizing high top quality materials, substantial good quality heat therapy. |

|

|

Promoting point 4 |

We can customise the motor parameters in accordance to the customer’s requirements. |

|

|

Promoting stage five |

We will give the very best after-sales support. |

|

|

Promoting point 5 |

ZYT collection long term magnet DC motors, with the advancement of people’s dwelling specifications and the improvement of modern manufacturing and workplace automation, family appliances, industrial robots and other products are turning into much more and much more charge-oriented, miniaturized and intelligent. As an important portion of the executive factors, the motor have to have the characteristics of substantial precision, substantial speed and high performance. The application of DC brushless motors is also thanks to the truth that This has led to fast development. |

|

NMRV NRV Sequence WORM Gear Speed REDUCER MOUNTING Proportions

PRECISION BEVEL Gear

20CrMn Ti content – low carbon alloy metal

Imported equipment grinding device processing, high hardness, steady performance.

Vacuum furnace carburizing heat therapy, carburizing layer uniform.

Higher Top quality SHELL Material

The box physique is manufactured of HT200 materials,which is cleaned by expert screening and washing products to make sure that the internal cavity of the box body is cleaner with out iron filings.

Substantial Top quality OUTPUT SHAFT

New normal axle, multi-precision machining, through arduous dynamic and static stability examination, to guarantee reduced noise and sleek procedure of reduOur factory has attained the certification of China’s Farm Equipment Merchandise Quality Authentication promulgated by the Farm Equipment Products Quality Authentication Centre of China. cer

Business Profie

Our firm is a popular producer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel gear, pulleys and racks in china.

We have exported a lot of goods to our clients all over the planet, we have long-time experience and sturdy engineering support.

Some of our buyer :

Italy: GB GEABOX, SATI, CHIARAVALLI, AMA, Brevini

Germany: SILOKING ,GKN ,KTS

France: Itfran, Sedies, Kuhn

Brazil: AEMCO ,STU

United states of america: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODS

Canada: JAY-LOR , CANIMEX ,RingBall

……

-> Our Firm with more than twelve year’s background and 1000 workers and twenty income.

-> With above one hundred Million USD income in 2017

-> With progress equipment equipments

-> With large function capacity and large high quality manage, ISO licensed.

Exhibition

Certifications

FAQ

Q: Are you trading business or manufacturer ?

A: Our group consists in 3 factories and 2 overseas product sales businesses.

Q: Do you offer samples ? is it free of charge or further ?

A: Of course, we could supply the saHow Can You Be Protected When Making use of PTO Shafts? First, make confident the shaft is shielded. This includes the driveline defend that addresses the employ driveline, and the grasp defend which addresses the universal joint and PTO stub shaft on the tractor.Maintain the protect so it can function for you. PTO driveline shields are generally mounted on bearings, so they want to be preserved. always REPLACE the shield when it is ruined or missing.Next, keep a secure length from it when in use. Hold other people absent, as well. How far? A distance of twice your top is a good start.Allow only those who definitely should be in the spot to be there. Hold all children away!Always shell out focus to what is happening. Most PTO victims have been caught by surprise.If anything goes mistaken — end the machinery take the PTO out of gear, stop the motor and set the brake. Set the keys in your pocket ahead of working on the machinery.When stopping the machinery for any explanation — end of function, lunch, repairs, or interaction — get the PTO out of gear, stop the engine and established the brake.Highway planers, dredges, and other gear demand power from some form of engine in buy to carry out their created perform. With out a energy take off, it would be essential to add a next engine to offer the power needed to run hydraulic pumps and other driveline attached gear.mple for totally free charge but do not pay out the price of freight.

Q: How extended is your delivery time ? What is your conditions of payment ?

A: Typically it is forty-45 times. The time might differ dependent on the item and the stage of customization. For regular merchandise, the payment is: 30% T/T in advance ,harmony ahead of shippment.

Q: What is the precise MOQ or cost for your item ?

A: As an OEM business, we can give and adapt our products to a broad variety of needs.As a result, MOQ and price may significantly vary with measurement, material and further specs For instance, pricey products or normal items will normally have a lower MOQ. Please speak to us with all relevant details to get the most exact quotation.

If you have an additional concern, make sure you feel free of charge to contact us.

Packing & Delivery

China manufacturer & factory supplier for RV-E in Basel Switzerland Series RV Robot REDUCER reduction gearbox trc gear box drive transmission robot gearbox With high quality best price & service

1 facet of our application consulting is that we have been gathering and combining the experience in chain and sprocket purposes in numerous locations for decades. This is particularly fascinating for us every time clients technique us with some exceeding and challenging specifications.We inspect each and every piece of bearing by ourselves before shipping and delivery.

Overview

Rapid Specifics

- ApplicableOUR High-Stop Phase: Discovering THE Ideal Answer FOR THE Buyer The large-finish phase typically calls for tailored options. In these instances, we supply you with in-depth consulting in get to devise a frequent remedy to meet your demands. Only then do we get down to the genuine operate. Industries:

-

Producing Plant, Machinery Repair Shops, Foodstuff & Beverage Factory, Farms

- Area of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Cycloidal

- Output Torque:

-

sixty five-34300N.m

- Enter Velocity:

-

750-3000rpm

- Output Pace:

-

five-60rpm

- Ratio:

-

56-192

Provide Capacity

- Supply Capability:

- 50000 Established/Sets per Yr

Packaging & Supply

-

How Can You Be Secure When Utilizing PTO Shafts? First, make confident the shaft is shielded. This involves the driveline defend that addresses the employ driveline, and the master defend which covers the common joint and PTO stub shaft on the tractor.Maintain the protect so it can perform for you. PTO driveline shields are usually mounted on bearings, so they need to have to be maintained. always REPLACE the shield when it is destroyed or missing.Up coming, preserve a protected length from it when in use. Hold others away, too. How much? A length of 2 times your top is a good begin.Allow only those who totally should be in the region to be there. Keep all children away!Always pay out interest to what is going on. Most PTO victims have been caught by surprise.If some thing goes incorrect — stop the machinery consider the PTO out of gear, cease the motor and set the brake. Place the keys in your pocket before doing work on the equipment.When halting the machinery for any reason — conclude of work, lunch, repairs, or communication — just take the PTO out of gear, cease the engine and established the brake.Road planers, dredges, and other gear need power from some sort of engine in order to complete their made perform. With no a power just take off, it would be necessary to incorporate a second engine to provide the electrical power needed to run hydraulic pumps and other driveline attached products.

- Packaging Specifics

- Stanard wooden circumstance, or wood pallet

- Port

- SHANGHAI PORT / NINGBO PORT

On the internet Customization

Merchandise Description

RV-E Sequence RV Robot REDUCER reduction gearbox trc gear box drive transmission

Application

Palletizing robotic,rotating work system,sorts of locator,robotic joints,mahine instrument,medical apparatus and instruments,ATC device,AGV driver, lid swap gear

E Series outline dimension drawing

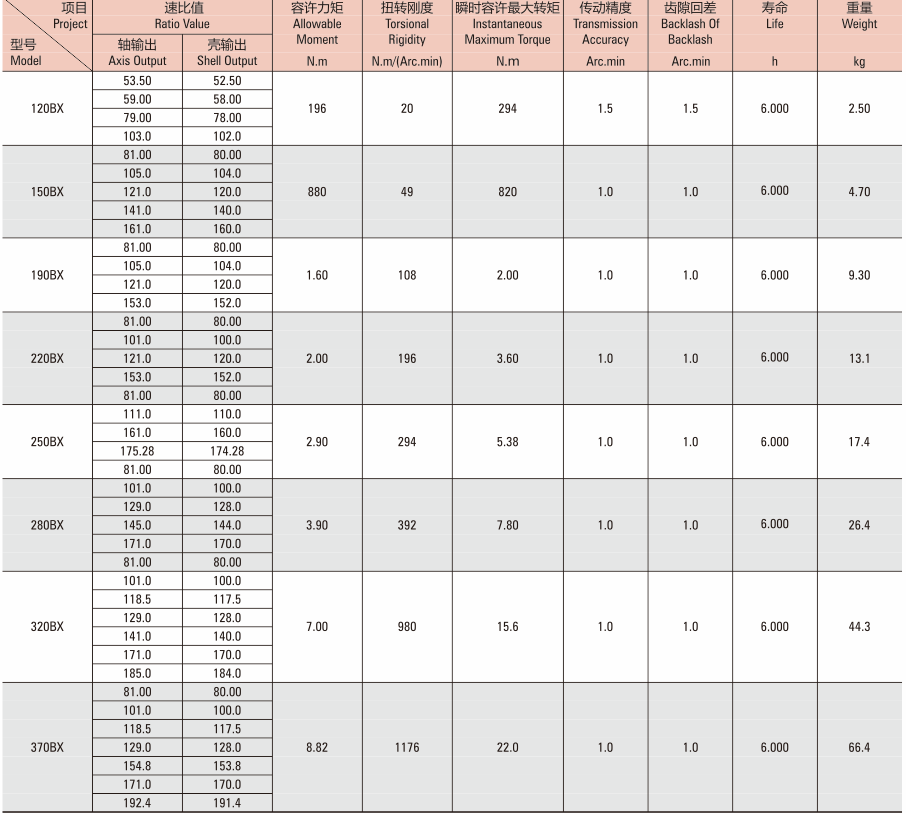

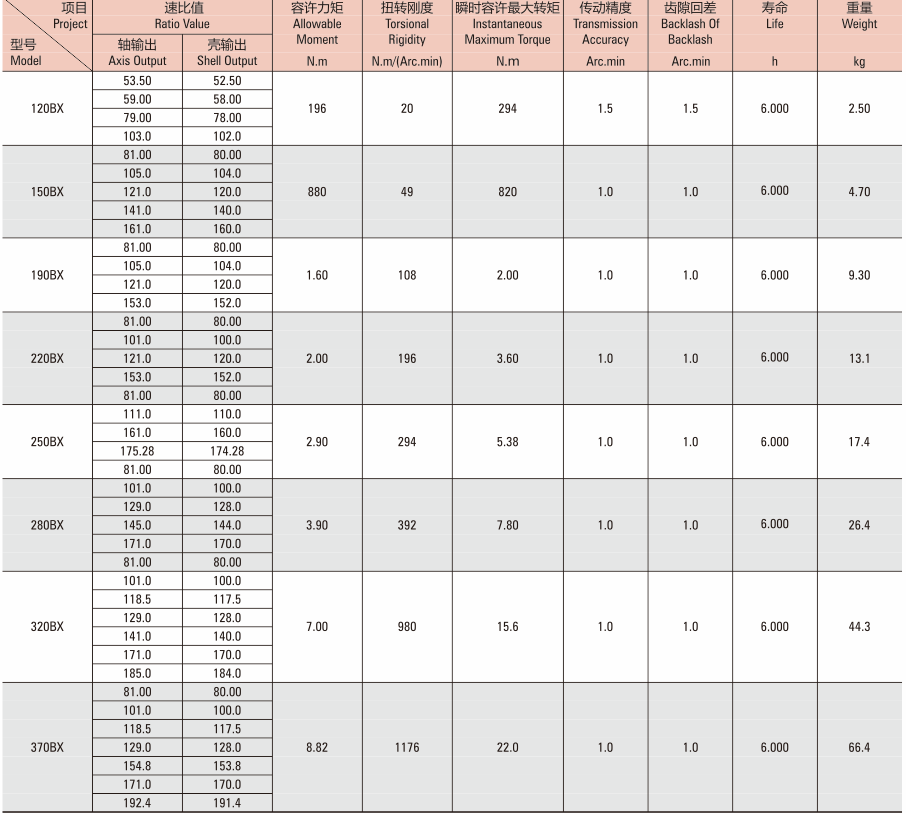

120BX-E Define Drawing

150BX-E Outline Drawing

190BX-E Define Drawing

Certifications

Trade Displays

Packaging & Transport

Company Data

other sequence solution

| PrecisionEPG brand rotocultivator ploughshares in T. line had been picked as the Nationwide Rotary Tillage Machinery Sector “Ideal Brand Items” in 2007 by Rotocultivator Department of China Agricultural Equipment Sector Association. Planetary gearbox | Robotic RV gearbox speed reducer |

| Custom created Non-standard Gearbox | UDL Series Variator |

| PYZ Series Helical Tooth Shaft Mounted Reducer | 8000 Series Cycloidal Reducer |

| SLT Series Spiral Bevel Gearbox | SLSWL Collection Worm Screw Jack |

| SLP Sequence Planetary Reducer | SLH/SLB Sequence Higher Electrical power Reducer |

| NMRV Sequence Worm Reducer | BKM Collection Helical-hypoid Reducer |

| SLRC Sequence Helical Reducer | SLSMR Series Shaft Mounted Reducer |

| SLXG Collection Shaft Mounted Reducer | X/B Sequence Cycloidal Reducer |

| SLR/SLF/SLK/SLS Sequence Helical Reducer |

Connected Products

Make contact with

Best China manufacturer & factory Factory in Mashhad Iran direct small 1:40 ratio electric motor gearbox With high quality best price

PersonnelOur sales persons are well trained to accommodate your requests and speak English for your cA novel design that uses a simple coil spring mounted in the breather’s air passageway solves the problem. The interior of the spring does not provide a continuous surface where bubbles can form, and this eliminates the percolating effect and resulting oil transfer.onvenience.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Gearing Arrangement:

-

worm

- Output Torque:

-

15~1700Nm

- Input Speed:

-

500~2800/min

- Output Speed:

-

5~560/min

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Product name:

-

small 1:40 ratio electric motor gearbox

- Application:

-

Food Stuff, Ceramics, Chemical, Packing, Dyeing,Wood working, Glass.

Maintenance Maintenance on these units is straight forward and like all moving parts these need their fair share of grease and should be greased regularly as these components work very hard and are subject to all that nature can provide for wear and tear. Good grease is essential here; put grease in until you see the old grease oozing out. Go easy on the “U” joints so you don’t blow the seals. Short bursts of a low pressured air grease gun or even better a hand pump gun will do the job and should be done based on hourly use. At least once a season the primary and secondary shafts should be separated. All debris and any rust should be cleaned off. Examine thoroughly for any signs of stress and apply a liberal amount of grease. In addition to this, both the PTO yoke holes need grease inside of them at least once a year along with the yoke lock pin.

- Color:

-

Blue(RAL5010)/Silver grey (RAL9022) Or On Request

- Ratio:

-

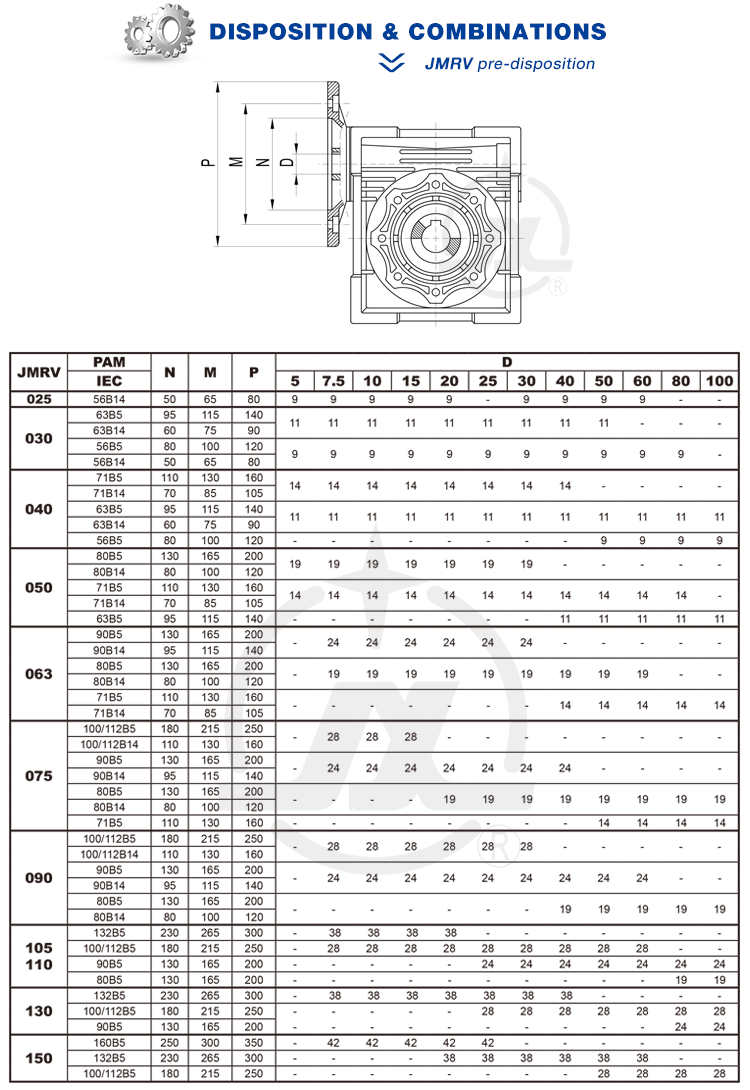

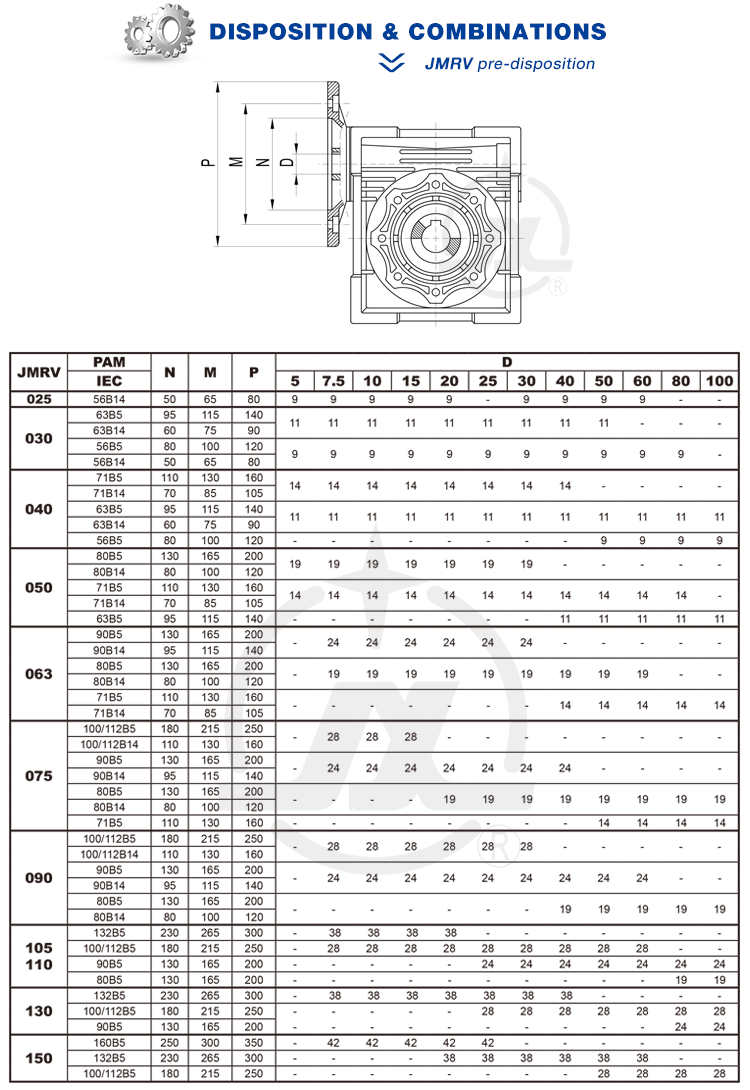

5,7.5,10,15,20,25,30,40,50,60,80,100.

- Warranty:

-

1 Year

Supply Ability

- Supply Ability:

- 36000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Transparent box packaging, or color box packaging, it also can be customized.

- Port

- Ningbo/Shanghai

Online Customization

Factory direct small 1:40 ratio electric motor gearbox